Power Plant Simulator & Designer is a world leading program for designing Steam generators, Heat exchangers and Balance of plants

It is easy to use with more than 2000 user and more than 150 licensees worldwide ->see users

Excellent support through experts

More than 100 different templates available -> see also examples

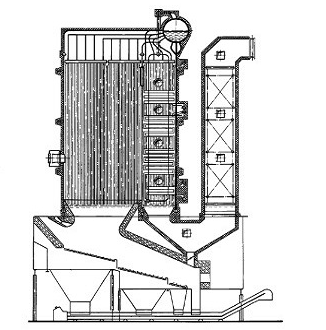

Steam Generators

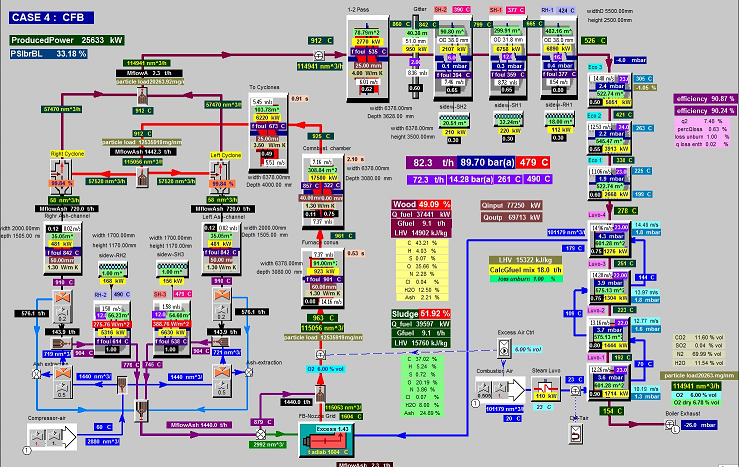

Designing and calculation of steam generators are the main uses cases with PPSD

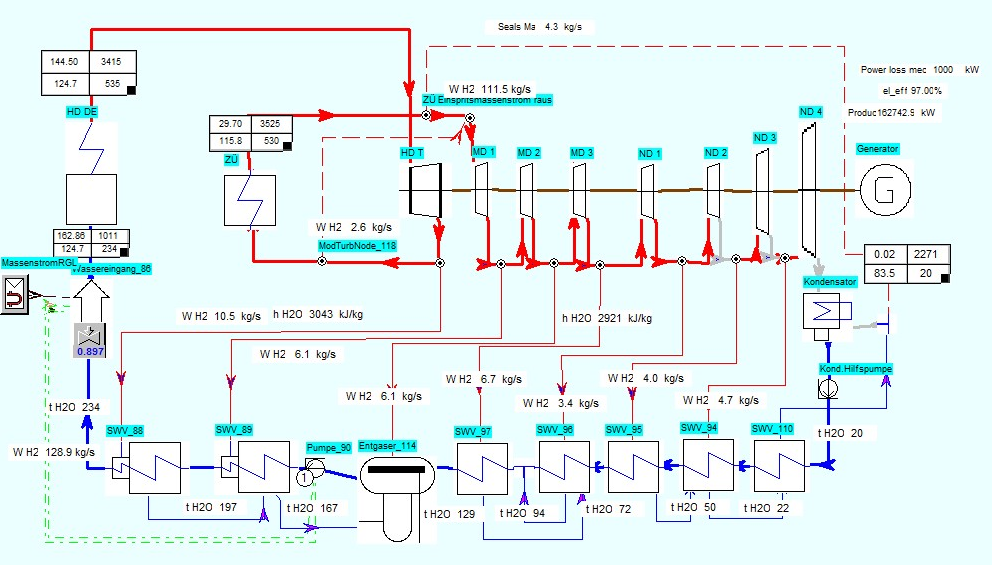

Balance of Plant

Steam Generators delivers in most times the steam to steam turbines and get back condensate

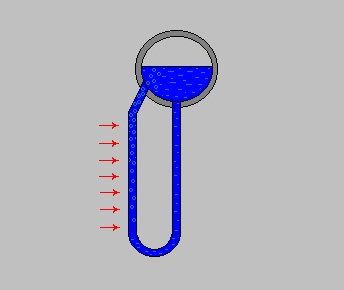

Natural circulation calculation

Tube bundle vibration

With PPSD you can calculate the tube bundle vibration and correct them with acoustic baffles and with supports like support tubes or support sheets

Combustion calculation

PPSD has a extreme robust tested combustion calculation with different fuels (gas / oil / liquids / solid fuels like biomass, municipal solid waste etc… it is possible to combust more than 100 different fuesl in one furnace.

PPSD has a big fuel database, the user can extend the fuel database

Different Fluids / gases

PPSD has a big medium database for ideal gases, real gases (with compressible factors), heat transfer oils, refrigants etc…

Unique features

Exact ash radiation from ash in the flue gas

Radiation between bundles and water wall / support tubes, this comes from experience due to mal performance in low load cases, it has been proven many times

Integrated natural circulation calculation

Easy switch to dynamic calculation (needs a dynamic license)

Your Dream. Our Mission.

We Believe In Hard Work And Dedication to Engergy Business

To reduce the carbon footprint we are supporting our users to design more effiecient and effective steam generators and power Plants

Some Examples

Balance of Plant

Balance of Plant with Reheat

1 Pressure HRSG

1 Pressure HRSG with duct burner

1 Pressure HRSG once through

1 Pressure HRSG with duct burner once through

1 Pressure HRSG forced circulation

1 Pressure HRSG with duct burner forced circulation

2 Pressure HRSG

2 Pressure HRSG with duct burner

2 Pressure HRSG vertical

2 Pressure HRSG with duct burner vertical

3 Pressure HRSG

3 Pressure HRSG with duct burner

3 Pressure HRSG Reheat

3 Pressure HRSG Reheat with duct burner

3 Pressure HRSG Reheat once through

3 Pressure HRSG Reheat with duct burner once through

3 Pressure HRSG Reheat supercritical

3 Pressure HRSG Reheat with duct burner supercritical

3 Pressure HRSG Reheat and solar power

3 Pressure HRSG Reheat with duct burner and solar power

D- Type Boiler saturated steam

D- Type Boiler Superheated steam

Monodrum boiler Vertical

Monodrum boiler Vertical Type Aalborg

Bi- Drum Boiler superheated steam

Bubbiling Bed Coal

Bubbling Bed biomass

Bubbiling Bed Coal bed cooling coils

Circulated fluidized bed combustion hot cyclone type Alstom

Circulated fluidized bed combustion hot cyclone type AEE

Circulated fluidized bed combustion hot cyclone type Lurgi with Ash coolers

Circulated fluidized bed combustion hot cyclone type FosterWeehler with Ash coolers

Circulated fluidized bed combustion cold cyclone tower type

Pulverized coal natural circulation

Pulverized coal once through subcritcal

Pulverized coal once through supercritical

Traveling grate coal / biomass natural circulation superheater

Traveling grate coal / biomass hot water

Pusher grate Municipal waste tail end

Pusher grate Municipal waste vertical

Pusher grate biomass vertical

Fire tube boiler superheater

Fire tube boiler reversal flame

Fire tube boiler hot water

Double Fire tube boiler superheater

Flue gas condensation -> to be integrated in all examples

Holland Boiler

Waste Heat Recovery boilers water tube

Waste Heat Recovery boilers fire tube

Steam Reformer

Heat Transfer Oil Heat Exchangers

Organic Rankine Cycle

Air heaters

Shell Tubes Heat Exchanges

Plate Heat Exchangers

Solar Power with hot oil

Solar Power with molten salt

More information about PPSD

PowerPlantSimulator&Designer

Program PowerPlantSimulator&Designer is designed for engineering complex heat exchangers e.g. steam boilers, power stations…etc

The PowerPlantSimulator&Designer allows the user to build quickly a graphical schematic representation for a plant in a graphical user interface (GUI) by selecting from a library of predefined power plant elements to simulate their operation. Element connections for fluid-flow paths, mechanical couples, or signal/logic flow paths are based on connectivity rules, defined for each element. The connection of elements is intuitively implemented with mouse operations allowing only valid connections.

Some elements are hierarchical and can hold nested groups. Such an organization helps to make schemes of complicated objects with no limitations on element quantity.

Different boiler types:

- Natural circulation boiler

- Forced circulation

- Force flow boiler (once through boiler)

- Benson-boiler (supercritical)

- Municipal waste incinerator

- Fire tube boilers

- Hot water boiler

- Fluidized bed combustion

- Other heat exchangersHeat transfer medium

- gases with real properties (Joule- Thomson- effect) (more than 20 different gases)

- all fluids (user defined)

- water with two phase flow

- dust and slag with infrared radiation

Technical features

- complete thermal calculation

- calculation of the pressure dropefficiency calculation

- all kind of recirculations

- A heat exchanger can be divided into zones to consider different temperatures and mass flows

- approx. 60 different elements (heat exchanger, spray cooler and so on) are available

- almost any combinations of heaters, coolers, combustion chambers are possible

- performance range from 100 kW to 1500MW

- hot water boiler ( shell tube, water tube and waste heat boiler)

- nominal load calculation i.e. presetting of steam weight flow: The temperatures, pressures and fuel consumption are calculated.

- easily part load calculation

- correct calculation of the vaporization in economizer

- combustion calculation and post-combustion

- high pressure flue gas possible

- heat exchange with real gases like CH4, H2 etc.

- working in the network

- graphical surface with icons and pull down menus

- user-definable fields for input and output

- C++ programming language

- executable with MS Windows XP/Vista/Win7/Win8 all 32 and 64 bit

user manual

documentation of calculation method (not everything because of conflict with copyrights)

training

one year charge free service (e-mail support etc. )

Other remarkable features

- Gas- Turbine exhaust gas can also be introduced into the combustion chamber. The turbine exhaust can be considered as oxygen carriers for the combustion calculation.

- the temperature at the end of the combustion chamber and fire tube can be entered.

- radiation from the combustion chamber can be transmitted onto the superheater bundles.

- turbine exhaust gas can be entered into Nm³/s or kg/s and/or the gas composition in Vol% or kg/kg.

- the thermal conductivity of the tubes is computed in dependence of tube material and the temperature.

- feed water pressure and the drum level are controlled automatically

- spray coolers and cooler in the drum are controlled by the temperature after the next heating surface.

- the fuel flow can be controlled in dependence of the desired steam production, independent of the steam temperature.

- several fuels can be mixed and burned

- calculation of efficiency (heat balance) in dependence of the exhaust flue gas temperature and composition, boiler surface conduction & radiation, loss in combustion chamber (unburned fuel), losses through ash and chemical not fully burned fuel (CO).

- design calculation of heater surfaces

- in almost every place of the flue gas draft can be taken recirculation flue gas and injected again not only in the furnace.

- flue gas flows and steam/water flows an be divided up and be combined again.

- statistical combustion calculation and net calorific value determination

Fluidized bed boiler

- Control of the ash flow parts to nearly all test points in the boiler

- Desulphuration with limestones

- Incomplete combustion and additional complete combustion

- Heat transfer for fluidized bed boilers and fluid bed heat exchangers

Usually for such number of calculations are used several programs and the results of the one program must be inserted manually into another program as initial data. That is one reason why the usage of the PowerPlantSimulator & Designer program gives such advantages:

- Fast calculation of the different boiler designs and as the result – helps to choose the best choice for projecting or reconstruction;

- Calculation of the transient stages on the projecting stage;

- Combine calculation of the heat scheme of the power plant with exact boiler calculation;

- Analyze static modes with different working conditions (fuel contents, dust presence on heat surfaces, feed water temperature difference…) and possible construction changes;

- Calculate natural circulation in drum-type boiler in current working mode and find minimum possible load by circulation condition;

- Analyze transient stages of the boiler (warm-ups, load changes…) in order to improve operational instructions of the boiler and future perfection of the startup devices;

- Unified elements and Graphic User Interface (GUI) minimizes time spending for the creation of the adequate mathematical model of the equipment. Qualified specialist in boiler construction can easily work with program, make and improve calculation models without any knowledge in programming;

- Comfortable data representation in Integrated Development Environment in different cases (data tables, tree views and graphs);

Ability of bi-directional data transfer between calculation program and Microsoft Excel for future data analysis and data representation.Mathematical model is adequate to real equipment because of:

- Application of the widely used calculation methods;

- Improved calculation method of heat exchange calculation, with division of the surface into small zones;

- Improved equations of the heat exchange considering the radiation, which was derived from the differential heat exchange equation, formulated according to physical processes specialties;

- Usage of the big database of the physical medium properties, which can be easily extended by user;

- Usage of the all-modes dynamic boiler model allows to calculate different stages with any combination of the disturbing influences with high static and dynamic precision;

- Usage of the special parameters, which characterize real state of the each heating surface, allows adapting mathematical model to the real equipment.Operational experience of the program usage confirms it’s highest efficiency and accuracy